Inventory & Order Management [info@ctomr.com]

![]()

Deliver up to 50% more on-time-in-full by ensuring your resources are in the right place at the right time

Our inventory management tools provide high-confidence

forecasts of future stock levels, allowing you to deliver more

effectively to your customers whilst at the same time saving money.

The model typically works from a list of inventory, stock or equipment that you need to manage, together with historical demand & ordering profiles.

The output of machine learning algorithms, based on your ordering and demand profiles, is presented across a simple dashboard, which forecasts where there might be upcoming gaps in supply against tolerances you set – giving you enough time to respond before becoming an issue.

As well as ensuring the forecasting methodology is fully customised to the specifics of your organisation and management approach, we use proprietary modelling techniques to interpret what can become quite complex implications of inventory shortfalls – for instance how gaps in shared resources impact activities with different priorities.

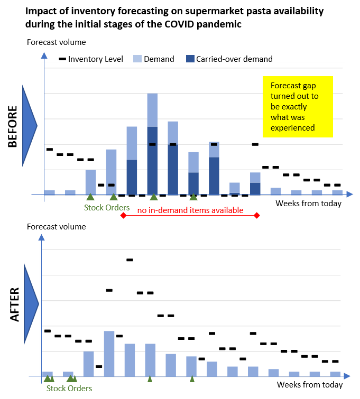

As well as helping assembly and manufacturing organisations manage stock levels & reduce delays in product completion, we more recently supported a supermarket chain to anticipate and avoid shortages at the start of the COVID pandemic – further validating the industry-leading predictive power of our models.

Contact us at info@ctomr.com or via our details below to see what we can do for you.

1.5x Impact: +25% resource availability, -20% less waste

- Correctly forecast 8-week gap in supply of in-demand food items March 2020 (e.g. dried pasta, etc.)

- Response avoided the gap and successfully coped with surge in demand

- Overall 80% reduction in cases of inventory shortfall

- Additional 20% drop in waste caused by excess inventory